Hackworth Valve Gear - Bill Perry

Background

:

As a bit of

background, my

I wrote the

article based on my experiences with

Regards. Bill Perry

Article :

Having visited

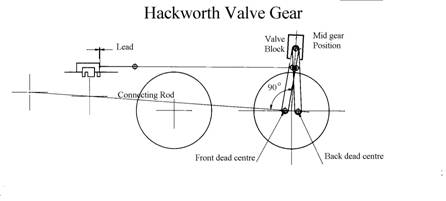

several shows, it is interesting to see the various set-ups of the Hackworth

Valve Gear on several “Sweet Peas”. It appears that despite all the articles

written about it people are unsure of the setting up procedure. This was

confirmed by a talk I had with a gentleman on one stand.

There is a method I have evolved, which, provided everything has been built to

the drawings, does not need any mathematics. This has been tested on two Sweet

Peas with good results.

1.

There must be no slop in any of the components of the

valve gear.

2.

Remove the cover on the valve chests.

3.

Set the wheels on the back dead centre, i.e. with the

crankpin in line with the connecting rod, not at 90 degrees.

4.

Place a small setsquare on the connecting rod and

check that the side of the valve block is at 90 degrees with the valve in mid

gear. Any adjustment required can be made by fitting packing between the

operating lever at the bottom of the valve block.

5.

Move the valve gear lever backwards and forwards and

check that the valve rod does not move. Adjust the wheel height to correct this

if required.

6.

Move the wheels to front dead centre and repeat step

5. If everything has been made correctly no adjustment should be required.

7.

Repeat the exercise on the other side of the engine.

Note that the valve block angle should be at 90 degrees if the blocks have been

set parallel.

8.

Any adjustment to the wheel height can have a small

effect on the other side due to the overhang so repeat step 5 again

9.

Now with the gear set at mid gear move the engine and

check that the valve shows an equal port opening on both sides of the engine.

Adjust the setting if required.

10.

Now with the valve gear set in forward, move the

engine and check where the valve port is just uncovered. Ideally with

everything tight this should be about 2 degrees before the dead centre. Check

at both front and back centres.

Note the valve block should not move more the 30 degrees about the mid point

when selecting forward or reverse.

11.

Move the valve gear to reverse and repeat the port

opening check while moving the engine in reverse. This should again be about 2

degrees.

12.

If the setting is at the dead centres the valve needs

shortening slightly equally at both ends, or as the linkage wears the valve

will be opening after the dead centres.

13.

Now link up the valve in forward and reverse and

observe the valve openings as before. The valve openings should be equal as

above, but with shorter cut-off.

What other modifications can be done to improve the

long-term operation of Sweet Pea?

1.

Replace the valve block in the slides with a bright

key steel one instead of the phosphor bronze one and lubricate with molybdenum

grease on fitting.

2.

The operating lever for the valve block should

connect to the top of the valve block. Examine the geometry with the valve in

full forward. The operating lever is trying to stop the valve block from moving

backwards and forwards with the engine operating. I know this requires

modification to the reversing lever to put the linkage below the pivot point,

but it is the ideal.

3.

Now that you have an engine that can link up, the

lubricator drive may not work if connected to the valve rod. A small bracket

connected to the bottom of the Hackworth valve link just above the crankpin

will provide a constant motion to the lubricator arm.